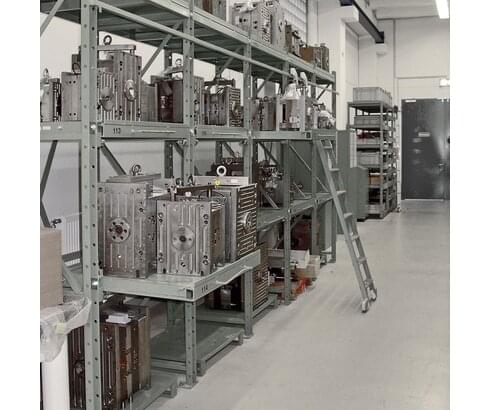

Rack Systems for Die Storage

Application

Rack systems with special roller conveyors or ball tables enable the user to change heavy dies safely, with less effort and in less time.

Mounted docking hooks or bars on the rack system enable precise positioning and safe docking on the rack system. An additional mechanical safety bolt or bar is automatically activated after docking to prevent dies from rolling out unintentionally after they have been stored.

Design and further technical details in the project and according to customer-specific requirements.

Please contact us!

Safety docking station

The docking station, consisting of two docking hooks or a docking bar, each mounted on the front of the rack system and die changing cart, enables precise and easy transfer of the dies.

Docking the hooks or bars lowers the safety bar and raises the ball bars in the changing table of the die changing cart.

The rack system can be equipped with roller conveyors or ball tables.

A mechanical bolt with spring return in the docking station on the rack serves as a safety device and is automatically activated when the die changing cart is undocked so that no dies can roll out unintentionally after they have been stored.

Versions

Rack systems with roller conveyors or ball table

• With docking hooks for die changing carts RW / RWA 500

• With docking hooks for die changing carts RW / RWA 1000

• With docking bars for die changing carts RWA 1600 – RWA 6000

Advantages

- Safe, force-saving and wear-free die storage

- Time-saving die change

- High level of safety due to docking station and semi-automatic, secured front bars or safety bolts as fall protection on the front side

- Optimum transfer height into the rack system and die changing carts

- Optimised for ROEMHELD die changing carts

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.