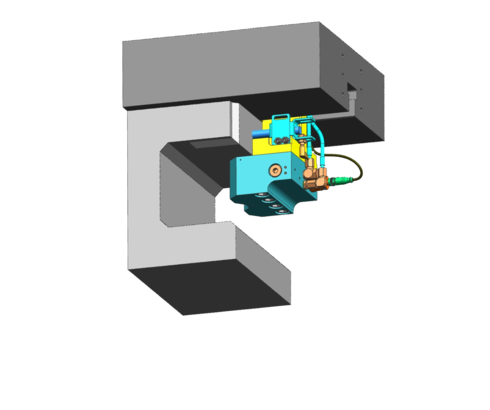

Rapid-Clamping System Flexline I 4.0 with Condition Monitoring

with "Condition Monitoring" for continuous monitoring of die clamping

Application

In automated die clamping systems for continuous monitoring of the clamping point or the manufacturing process.

Description

The rapid-clamping system Flexline I 4.0 is equipped with sensors that continuously measure the clamping force and clamping pressure of the used clamping element in real time.

Thus the condition of the die clamping is recorded and monitored. Unusual stripping forces in the die or an overload at the clamping point can be detected and suitable measures can be taken immediately.

The measured data can be transferred to the press control and evaluated via a data interface, e.g. IO-Link.

As an alternative, a control with evaluation software can also be supplied, which graphically displays the status of the die clamping in a forcetime diagram.

A further sensor enables conclusions to be drawn about the degree of contamination of the pressure medium, from which maintenance measures can be determined to prevent the clamping element from failing.

Advantages

- Continuous condition monitoring – detection of stripping forces in the die

- Tool breakage and wear detection

- Avoidance of downtimes

- Maintenance detection – fast troubleshooting

- Remote maintenance option

- Process stability

Measured data and evaluated information

- Clamping force in real time

- Overload of the clamping element

- Unusual stripping forces

- Process forces at the clamping point or die

- Error analysis by recording the clamping force curve

- Protocol for the service case

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.