While many stamping companies are struggling with a slump in orders, Feintool in Obertshausen is operating at full capacity. The site near Offenbach is fully booked until 2030. Around 240 employees work in three shifts to produce up to 60,000 parts for the automotive industry every day. Modern stamping technology, consistent automation and reliable clamping technology from ROEMHELD contribute to this success.

At a time when many press shops in the automotive supply industry are struggling with sluggish orders and short-time working, Feintool System Parts Obertshausen GmbH is an exception. In three shifts, around 240 employees manufacture up to 60,000 parts for the automotive industry every day. "We work 35 hours according to the collective agreement, have no short-time working, and even do extra shifts on bottleneck machines," reports André Gansen, plant manager at Feintool System Parts Obertshausen.

He has been managing the plant, which Feintool took over in 2012, for seven years. "We are an island property and didn't have room for additional equipment at the time. So we examined every piece of equipment and every tool, and restructured the processes and material flow. We turned everything upside down back then," says Gansen. The basis for the turnaround was a major order from Stellantis, which Obertshausen was able to land in an internal bidding process with the other Feintool Group locations.

It comprises the production of seven different components with heights between 78 mm and 302 mm, each with an annual volume of 1.2 million units. These are drive components for conventional combustion engines and hybrid drives. Other customers also placed orders for products that are used in hybrid or electric drive concepts. Another requirement was that each item had to be individually packaged.

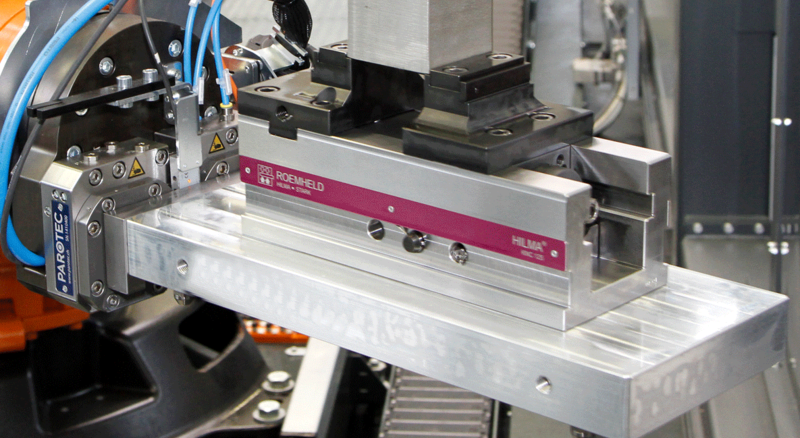

In order to be able to produce these quantities efficiently and adequately, Feintool invested in two 2,000-tons multi-stage presses from Schuler, including peripherals. The initial equipment for the systems included 100 angle clamps from ROEMHELD as die clamping devices.

In addition, the employees developed two suitable fully automatic packaging lines for the presses. "Everything is state of the art," says Gansen, describing the technical equipment. "We developed the best production concept at the time and, of course, we were also lucky that such an order was placed on the market."

On the new Schuler systems, the components are first cut from the coil and then pressed in a twelve-stage forming process. This means that a separate set of twelve dies is required for each part. Each upper die is fixed with four angle clamps, meaning that one die set requires 48 angle clamps. With the 100 angle clamps available, Feintool can clamp the complete die sets for both Schuler presses. Four additional reserve clamps are kept in stock.

The lower die parts can be screwed onto changeover tables without affecting production time.

A die change is usually required after every third shift. This takes less than an hour – including all adjustments and clamping operations. To release the spring force, the angle clamps are manually moved out of the clamping area and then moved back to the head plates for positioning. Hydraulic clamping is then carried out via the machine control system. The simple and quick handling of the clamping devices helps to keep machine downtime to a minimum, reports Gansen: "All 48 angle clamps in a die set are clamped in two minutes."

The decision to use ROEMHELD angle clamps is based on many years of positive experience. Feintool in Obertshausen has been relying on clamping technology from the Laubach-based company since 1999, including swivel clamps and transport bars.

The hydraulic angle clamps with T-slot base used are single-acting with spring return and designed for a maximum operating pressure of 400 bar. Despite their compact design, they offer clamping forces of 40 to 110 kN. They can be used on ram and machine table – even with narrow clamping edges. A particular advantage is their versatility: ROEMHELD angle clamps can be used flexibly with different head plate thicknesses and in confined spaces.

"We have also had good experiences with the angle clamps: they are simple, robust, reliable, low-maintenance and easily accessible," says Gansen, summarising the advantages. Eray Yaman, Deputy Head of Mechanical Maintenance, is also very satisfied: "They work great, we haven't had any problems yet, and even after a hundred uses, they clamp just as well as they did the first time."

Feintool keeps a total of 90 active die sets in stock, with additional sets available for spare parts production. The company manufactures and repairs all dies entirely in-house. "There are no duplicate sets per component – that would be too expensive," explains Gansen. "We have replacements for heavily used wear parts such as sliding elements so that we can replace them quickly."

Production is fully automated and therefore very competitive: after the forming process, the components are transported from the presses via conveyor belts, washed and packaged without human intervention. "Our goal is to have no people standing behind the equipment," emphasises Gansen. Only two employees are involved in the entire manufacturing process, from coil delivery to storage of the finished parts.

Feintool Obertshausen processes around 60 tonnes of steel per day in this fully automated process. This amounts to 16,000 to 18,000 tonnes per year, with 90 per cent hot-rolled strip and 10 per cent cold-rolled strip currently being used.

"Such a complex process only pays off if all components and systems function reliably," explains Patrik Dellmer, Head of Technical Services. "And because the clamping technology offers this reliability and spare parts procurement also works excellently, we rely on ROEMHELD," confirms Gansen. With a machine park of 200 systems – from washing machines to Schuler multi-stage presses – this reliability is crucial.

The 62-year-old plant manager is optimistic about the future. Feintool Obertshausen supplies parts for 27 car models from the Stellantis Group alone, and other well-known customers include Daimler, BorgWarner and GKN.

The global orientation and balanced product mix create stability in a changing market. "Hybridisation will take longer, and pure e-mobility will come more slowly than we think," predicts Gansen.

He believes the plant is well positioned because it manufactures components for conventional, hybrid and, increasingly, purely electric drives. His goal: "We want to hand over the site to the next generation in a competitive state."

Committed workforce

He is also encouraged by the dedicated workforce. He cites logistics and process automation as an example. A high-bay warehouse with 3,600 storage locations was created, which is managed by robots. The employees developed an innovative solution for automated packaging handling. With their help, six of the seven components of the new order can be packed in two special load carriers. They succeeded in standardising the trays with the same external dimensions. The seventh part is packed separately. "We did it all ourselves – without external help," explains Gansen, not without pride.

We are here for you.

Do you have questions about your customer account, enquiries or orders? Please feel free to contact us.

Aproveche nuestra zona de login gratuita:

- Descarga de datos CAD

- Descarga de instrucciones de servicio

¡Bienvenido de nuevo! Inicie sesión con su cuenta de usuario ya existente.'