A model for safe and self-locking long-term clamping of dies with straight clamping edge completes the ROEMHELD Group's series of new wedge clamps. The element for the clamping of dies on presses and injection moulding machines does not require a permanent hydraulic supply. Spring force is applied for fixing and only a pressure of up to 160 bar is required for release. The machine hydraulics can therefore be used in this regard.

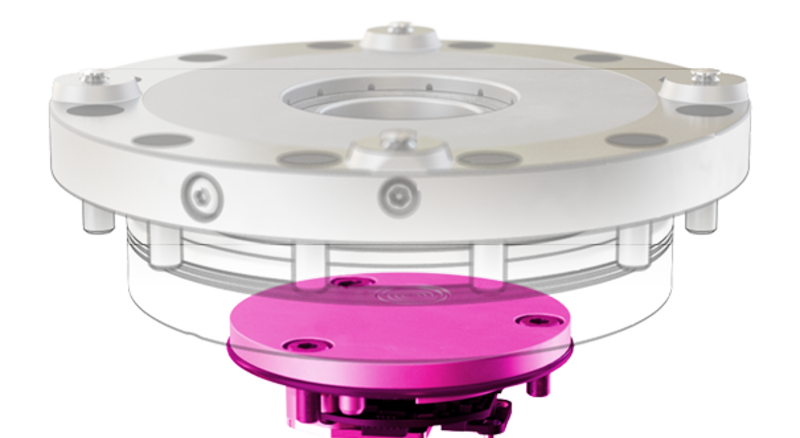

A high degree of operating safety is guaranteed by way of an inductive and additional optical position control and the special design of the clamping device: The clamping bolt is inclined 6° and executes an idle stroke and clamping stroke simultaneously with the fixing action, whereby it is lowered down onto the clamping edge in an axial direction. A self-locking connection is resulted from the angle, the application of spring force and the effectuated frictional connection, and this can be maintained over lengthy periods of time.

As the compact and robust wedge clamps can easily withstand environmental influences such as heat and dirt, they are characterised by their high functional safety, even in the most challenging production processes. Temperatures of up to 160°C are possible at the clamping point, and the housing is coated with a rust protection.

Variant system allows individual customer adaptations

The wedge clamps are constructed as a variant system and can be adapted for numerous applications. Even in the standard range, four possible hydraulic connections provide flexibility for assembly, the dimensions of the clamping element comply with the Euromap Directives. The tolerance for the clamping edge height is ± 0.5 mm and deviations can be compensated with spacer plates. The operating force is 25 to 120 kN, depending on the respective design size, and the cylinder diameters are between 35 and 85 mm. Additional versions are available for angled clamping edges, with permanent lubrication or multi-layer coating to improve wear properties.

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.