Fertiliser prices at record levels and the increase in large agricultural areas are boosting business with precision spreaders from Rauch Landmaschinenfabrik GmbH. Electrical linear actuators are among the most important components to ensure that each fertiliser is optimally distributed according to the travel speed, soil conditions and field geometry.

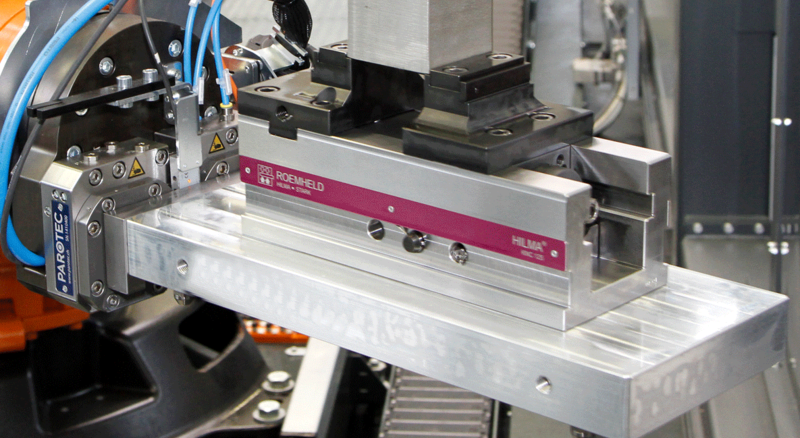

Actuators are used, which Rauch has developed together with the specialist ROEMHELD.

“One of the reasons for the worldwide leading position of the German agricultural technology industry is the German reunification”, explains Jens Hille, Head of Marketing at Rauch Landmaschinenfabrik GmbH, based in Sinzheim, Baden. Since the machines of German manufacturers were not always suitable for the large areas of East German farms, the suppliers had quickly expanded their range of products with appropriately dimensioned machines.

This laid the foundation for today's success in Eastern Europe, said the head of marketing, whose employer is riding a wave of success. Hille explains: “At present, new export markets are opening up for us all the time.” The reason: International investment funds from Europe, Japan and North America, but also China and India are currently buying up huge agricultural areas, especially in Africa and South America, and equipping their farms with the best and latest machinery. Hille’s employer benefits from these developments and the head of marketing is happy about it: “Metering spreaders from Rauch are successful worldwide.”

The trend towards larger and faster agricultural machinery is one of the factors driving innovation in the industry. The most important reason for growth, however, according to Hille, is the high price of fertilisers: Not only have raw material prices for potash and phosphorus increased enormously but also the energy costs for production have risen sharply. Thus, the investment in an efficient fertiliser spreader is particularly worthwhile today.

The size and thus also the unit price of the machines in demand is increasing. Rauch sold a total of around 15,000 machines in 2012; the 360 employees achieved a turnover of € 70 million - more than ever before. The core business is focused on Europe and Asia - a total of 39 countries worldwide, with exports accounting for around seventy per cent.

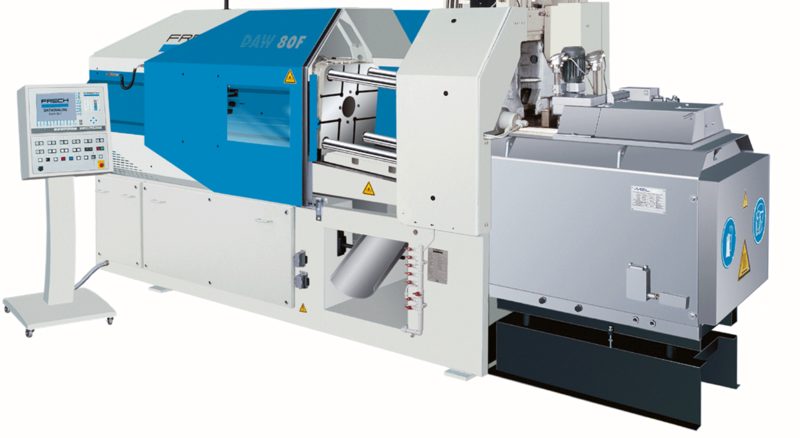

For large cultivation areas, Rauch offers the current flagship “AGT 6036” with a payload of 6.2 tonnes and a working width of 36 metres at a list price of around € 135,000. “With the current model, we have not yet reached the end of the line in terms of size,” predicts the head of marketing.

“The efficiency of our machines is based on their long service life and high precision,” explains Hille. The electric drives, which are now used in around seventy per cent of the twin-disc fertiliser spreaders of the best-selling “Axis” and in AXEO winter service spreaders, particularly meet these quality standards. According to the head of marketing, “our high-tech machines are equipped with high-quality electric actuators from ROEMHELD.

The cooperation between the two companies began eight years ago. “We are always looking for improvements and have found a system partner for one of the most important components in ROEMHELD who shares this passion”, Hille explains the decision for the specialist who develops and manufactures the linear actuators in Laubach near Gießen in Hesse. Together, the experts of both companies have developed an actuator that is tailor-made for Rauch's needs.

Of course, the components should function reliably for many years. The head of marketing explains: “If the farmer uses our fertiliser spreader continuously from February to the end of May and in all weather conditions, the machine must always be ready for use – even if it has been standing for the previous eight months.” All greases, oils, seals and the entire electronics must then be fully functional immediately.

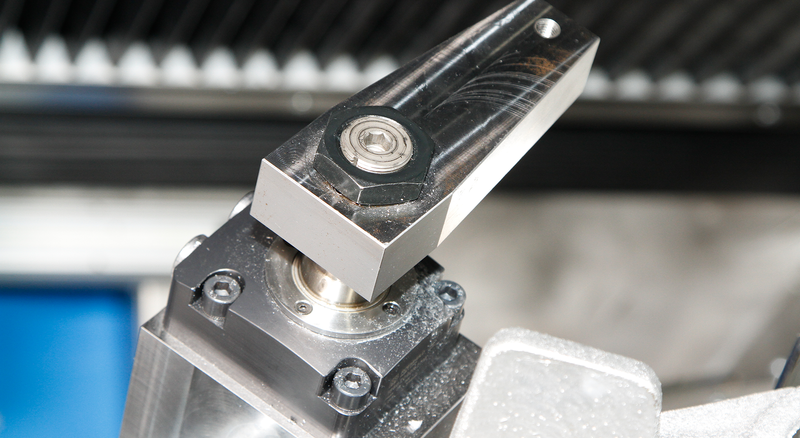

For efficient corrosion protection of the actuator, the development teams of Rauch and ROEMHELD have agreed to use a pushing rod made of special stainless steel and a particularly robust sealing technology. Thus, they have achieved that the linear actuator exceeds the requirements of the protection class IP69K. The component can withstand the very rough minerals, road salt and aggressive chemicals as well as constant wetness and can also be easily cleaned with a high-pressure cleaner.

Whereas Rauch machines used to rely primarily on mechanics and hydraulics, the proportion of electronic components today is forty per cent. Consequently, half of the 36 employees in the research and development department are software developers and electronics engineers. In 1984, the company was the world's first supplier to use electronics in agricultural machinery with its “Quantron” operating terminal. For 29 years now, electronic actuators have been used in addition to hydraulic actuators. Regular awards at international trade fairs such as Agritechnica, Sima, Eima and Agribex show the recognition that Rauch's metering and control systems have earned.

In the past, a hydraulic drive only had the task of opening and closing a metering slide valve, but in the meantime the requirements have changed considerably. High-precision control systems are required that adjust the metering rate to the travel speed and working width and automatically regulate the flow rate. Accuracy and fast reaction are necessary, emphasises Hille: “Rauch AutoFlow systems, the weighing technology and the electronic mass flow control EMC, constantly measure the flow of fertiliser via sensors. This provides the information which, in the end, determines the target position of the actuator once per second. The directly coupled stroke measuring system in the actuator ensures that the fertiliser mass flow of the fertiliser is always optimal.”

Besides the high speed at which machines drive over the fields today, modern spreaders also take into account the nature of a plot when fertilising. Thanks to GPS control with fertiliser application maps, not only the exact geometry of a field but also the type of soil and its nutrient content are taken into account when fertilising. The head of marketing explains: “The farmer can load the information onto a chip on his computer and then transfer this information to the control system. The actuators then control the metering unit with high precision for this sub-area specific fertilisation.” Corners, edges and wedge areas of plots can be spread with the correct fertiliser quantity and spreading width using the VariSpread width section control and “remote-controlled boundary and edge spreading”. When turning at the headland, the slider automatically closes the metering opening with OptiPoint at the optimum point and prevents spreading errors.

The prerequisite for this high metering and spreading accuracy are ROEMHELD linear actuators, which approach the respective feed points with sensitivity, precision and speed,” explains Jens Hille. This was particularly taken into account when choosing the supplier. In the joint development of the actuator, the focus was on smooth integration into the overall machine processes and into the control program of the Quantron operating terminal.

The vision of a twin-disc fertiliser spreader that can be completely controlled from the cab has already been realised in the “AXIS-H 50.1/30.1 EMC+W ISOBUS”, where all functions can be set and controlled at the terminal. “The share of electronics will continue to increase in the future”, believes the head of marketing.

Consistency at a high level is the goal for the quality of Rauch products. For this reason, the family-owned company, founded in 1921, maintains one of three test halls at the Baden-Airpark site, where it tests the behaviour of around 3,000 different types of fertiliser. The behaviour of the fertiliser varies depending on the material, size and geometry of the grain.

Long-term system partnerships such as the one with ROEMHELD are essential for the quality. Other factors are the high vertical range of manufacture (eighty per cent) and comprehensive incoming inspections of deliveries. These are not necessary for the electric linear actuators that come from Laubach, Hille reveals: “We can rely on the 100 per cent outgoing inspection and quality at ROEMHELD.”

genesis of an actuator

We are here for you.

Do you have questions about your customer account, enquiries or orders? Please feel free to contact us.

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.